Compressed air, a vital energy source, permeates nearly every industry, with 70% utilising it in some aspect of their operations. A huge and diverse range of businesses based in the East of England rely on compressed air for their operational processes. With multiple industrial sectors requiring different levels of air purity, whether powering pneumatic tools, packaging and automation equipment and conveyors. This is because compressed air is a dependable channel for transmitting power to control devices in production and non-manufacturing operations.

The Healthcare, Laboratory, and pharmaceutical sectors have high standards for compressed air quality, though the specific requirements, environments and regulations all vary slightly.

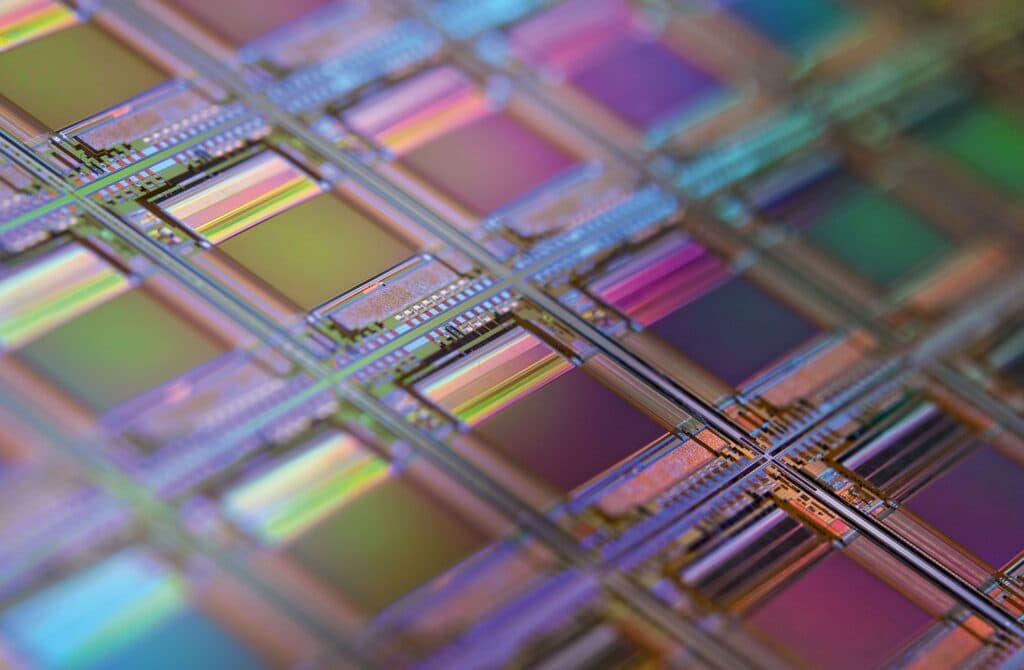

Maintaining ultra-clean, contaminant-free compressed air is paramount. Even a speck of dust or oil can ruin a delicate circuit board, making clean air critical for flawless product quality and successful electronics and high-tech manufacturing.

In the Food & Beverage sector, maintaining high-quality compressed air is essential to ensure product safety and integrity. Compressed air is used in various critical processes such as packaging, filling, conveying, and cooling.

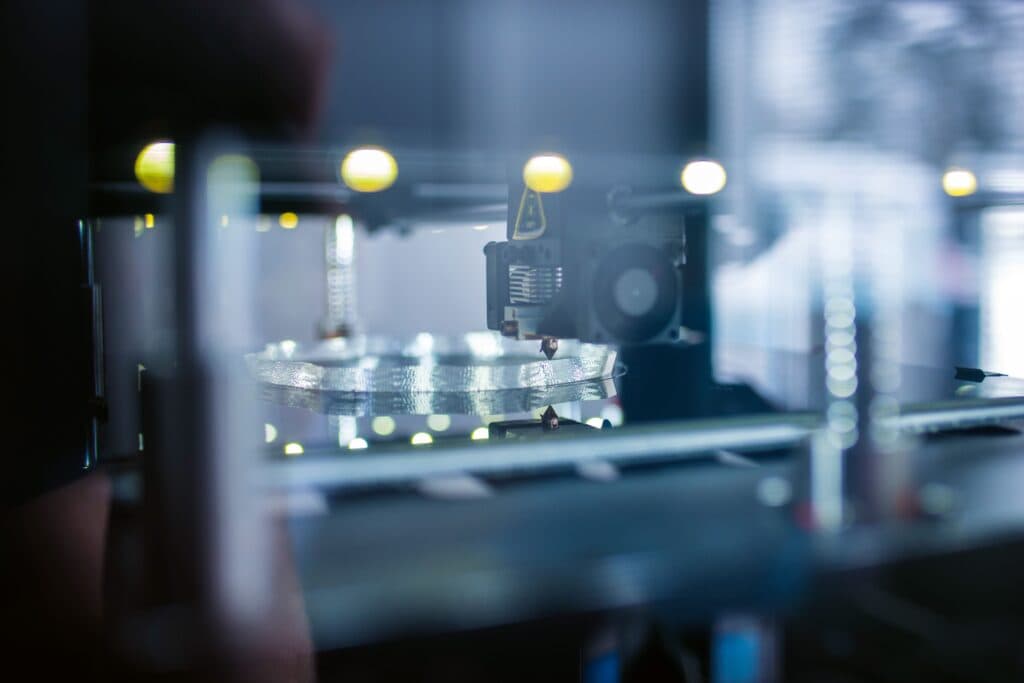

Industrial manufacturers and engineers rely heavily on compressed air as a versatile and powerful utility. It fuels a vast array of processes, from powering material handling and conveying to assembly line equipment. It maximises efficiency across your entire manufacturing and engineering operation.

In the agriculture, growing, and packing sector, maintaining high-quality compressed air is vital for ensuring the health and safety of produce and efficiency of operations. Minimising product damage, optimising efficiency, helping you deliver high-quality produce to market.

Maintaining high-quality compressed air is crucial for ensuring the efficiency and effectiveness of the water treatment processes. Compressed air is integral to aeration, pneumatic conveying, backwashing filters, and operating valves and actuators.

Compressed air in the chemical industries powers vital processes like mixing, conveying, and even helps ensure safety through instrument operation. Maintaining clean, high-quality air is crucial.

Compressed air is used in instrumentation, control systems, combustion control, pneumatic conveying and turbine operations. Precision and contamination-free air are critical to biomas & energy generation production.

In automotive and aerospace, compressed air is a critical force for both large-scale manufacturing and small workshops. Maintaining high-quality compressed air is critical for ensuring precision, reliability, and efficiency in various applications from painting and surface prep, pneumatic tools, component testing and cleaning.

In the fast-paced world of logistics and warehousing, compressed air everywhere, from maintenance workshops to inflating packaging materials, operating machinery and propelling packages and goods along sorting lines – ensuring smooth and rapid distribution.

In the challenging environment of construction, quarrying, and aggregate production, maintaining high-quality compressed air is essential for powering pneumatic tools, equipment, and machinery used in drilling, breaking, conveying, and material handling.

Maintaining a reliable compressed air system ensures efficient material separation, minimises contamination, and helps you deliver clean, high-quality recyclables back into the manufacturing loop.